3D Fabrication Software

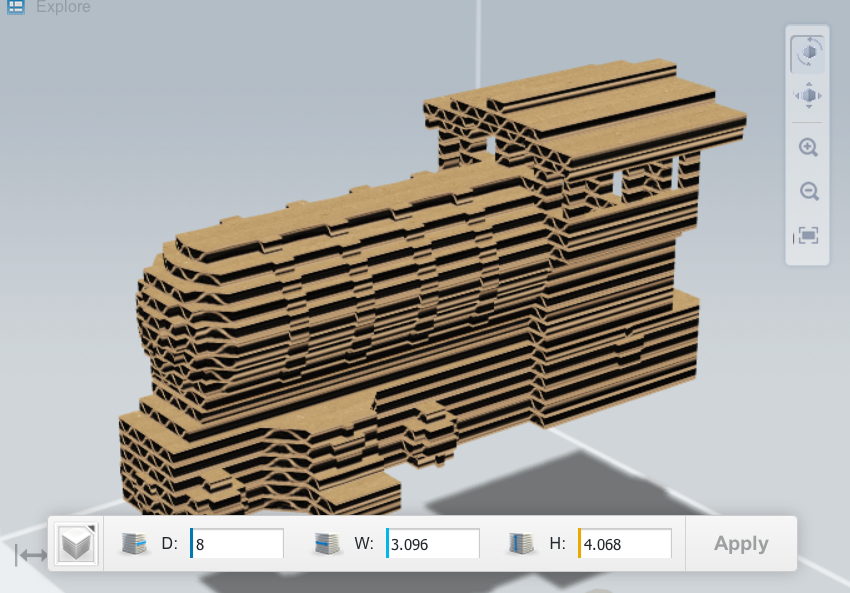

ZrGLBN_I01wW2WkTPNMoMkTOF8ALCPxhulDM643uSuxpf6mY9GzETNE6fyY4mVgUlT_NXucT-gvsuN2-mITcw7G4B8VA74=w506-h303-p' alt='3D Fabrication Software' title='3D Fabrication Software' />D Printing and Investment Casting Make a Perfect Fabrication Team 3. DPrint. com. Not only is 3. D printing a wonderful, versatile method of fabrication on its own, but its also turned out to play an important role alongside other, much older techniques in many cases. Investment casting is one of the oldest manufacturing methods in existence, and although it was first used thousands of years ago, its still a common, useful method of creating metal pieces today. D printing, also known as additive manufacturing AM, refers to processes used to create a threedimensional object in which layers of material are formed under. Autodesk has a variety of software solutions for manufacturing. View our products for CNC machining, fabrication, modeling, composites, additive, and metrology. D Fabrication Software' title='3D Fabrication Software' />D printing has complemented it well, proving that even reliable, time tested techniques can benefit from new technology. Also known as lost wax casting, investment casting involves the creation of a wax model, or pattern, in the shape of the final part. Its then coated in ceramic and placed into an oven, where high temperatures burn away the wax, leaving a ceramic mold behind. Molten metal is then poured into the mold and allowed to harden, creating the final part. D printing has become a popular way to fabricate the initial model, especially in the creation of jewelry. Certain 3. D printer manufacturers, such as Formlabs, have created wax and resin materials specifically for casting, but good old PLA can do the trick as well. Jerry Le. Pore, CEO of Spectra. D Technologies, can vouch for that. Le. Pore joined Spectra. D in January of this year, two years after he began working with 3. D printing. The Asheville, North Carolina based company began as a 3. D printer reseller, and this summer started offering 3. D Fabrication Software' title='3D Fabrication Software' /> Rhino can create, edit, analyze, and translate NURBS curves, surfaces, and solids in Windows. There are no limits on complexity, degree, or size. Rhino also has. D printing services as well. One of their early customers was Flowserve, a global supplier of pumps, seals, valves and other engineering solutions. Paladin Build Patch 3.3.5. Flowserve asked Spectra. D to print patterns for the investment casting of parts including valve bodies, ball valves, pump housings, and impellers. Le. Pore, already a big fan of color. Fabb materials, figured that their PLA would be perfect for the job. Fl Studio 11 Regkey'>Fl Studio 11 Regkey. We chose Colorafab natural PLA because it contains no color pigments, prints great and burns out really clean from the mold, he said. Currently we are going through 2. D Fabrication Software' title='3D Fabrication Software' />Colorfabb Natural. The color. Fabb materials are supplied to Spectra. D by Printed Solid, a distributor based in Newark, Delaware. Fused deposition modeling FDM is an additive manufacturing AM technology commonly used for modeling, prototyping, and production applications. Autodesks 3D CAD design software helps users design ideas, visualize concepts, and simulate how designs will perform in the real world. New Style Bangla Font. For detailed focus on specific capabilities of this system visit these sites structural steel beams plasma cutting structural steel fabrication machinery. Once Spectra. 3D prints the patterns, they are sent to Flowserve, which fills them with molten titanium, stainless steel and other metals. Using 3. D printing to create the patterns saves time and money PLA is an inexpensive alternative to wax, and 3. D printing allows a design flexibility thats difficult to achieve with other methods of fabrication. I started using colorfabb filament early 2. Le. Pore said. We believe in using high quality filament for our clients needs. We have used all of color. Fabbs filaments across the board. Fabbs PLAPHA material was developed four years ago by combining polyhydroxyalkanoate PHA, a biopolymer, to PLA to create a tougher, less brittle version of the filament. The company offers a wide variety of colors solids, translucents, metallics, and transparent shades, from classic primary colors to highly specific shades such as blueish white and greenish beige, as well as, of course, the Natural version which worked so well for this particular application. Image Marshall Miller at FlowserveLe. Pore used the industrial STACKER S4 3. D printer, which he calls his pride and joy, for the large casting patterns. Also in his repertoire are several Maker. Bot printers as well as Craft. Bots, a Creator. Bot 3. D Pro, a Fusion. 3 F3. Print SE Plus. Discuss in the Investment Casting forum at 3. DPB. com. SourceImages color.

Rhino can create, edit, analyze, and translate NURBS curves, surfaces, and solids in Windows. There are no limits on complexity, degree, or size. Rhino also has. D printing services as well. One of their early customers was Flowserve, a global supplier of pumps, seals, valves and other engineering solutions. Paladin Build Patch 3.3.5. Flowserve asked Spectra. D to print patterns for the investment casting of parts including valve bodies, ball valves, pump housings, and impellers. Le. Pore, already a big fan of color. Fabb materials, figured that their PLA would be perfect for the job. Fl Studio 11 Regkey'>Fl Studio 11 Regkey. We chose Colorafab natural PLA because it contains no color pigments, prints great and burns out really clean from the mold, he said. Currently we are going through 2. D Fabrication Software' title='3D Fabrication Software' />Colorfabb Natural. The color. Fabb materials are supplied to Spectra. D by Printed Solid, a distributor based in Newark, Delaware. Fused deposition modeling FDM is an additive manufacturing AM technology commonly used for modeling, prototyping, and production applications. Autodesks 3D CAD design software helps users design ideas, visualize concepts, and simulate how designs will perform in the real world. New Style Bangla Font. For detailed focus on specific capabilities of this system visit these sites structural steel beams plasma cutting structural steel fabrication machinery. Once Spectra. 3D prints the patterns, they are sent to Flowserve, which fills them with molten titanium, stainless steel and other metals. Using 3. D printing to create the patterns saves time and money PLA is an inexpensive alternative to wax, and 3. D printing allows a design flexibility thats difficult to achieve with other methods of fabrication. I started using colorfabb filament early 2. Le. Pore said. We believe in using high quality filament for our clients needs. We have used all of color. Fabbs filaments across the board. Fabbs PLAPHA material was developed four years ago by combining polyhydroxyalkanoate PHA, a biopolymer, to PLA to create a tougher, less brittle version of the filament. The company offers a wide variety of colors solids, translucents, metallics, and transparent shades, from classic primary colors to highly specific shades such as blueish white and greenish beige, as well as, of course, the Natural version which worked so well for this particular application. Image Marshall Miller at FlowserveLe. Pore used the industrial STACKER S4 3. D printer, which he calls his pride and joy, for the large casting patterns. Also in his repertoire are several Maker. Bot printers as well as Craft. Bots, a Creator. Bot 3. D Pro, a Fusion. 3 F3. Print SE Plus. Discuss in the Investment Casting forum at 3. DPB. com. SourceImages color.